So here it is. The very first "print" test from Shapeways.

First of all, they are VERY delicate. So delicate that the jump ring on one of the pieces fell off with very minimal handling. That's actually a good thing, because it tells me I need to beef these up a little. But there are some other design issues that I'll have to address.

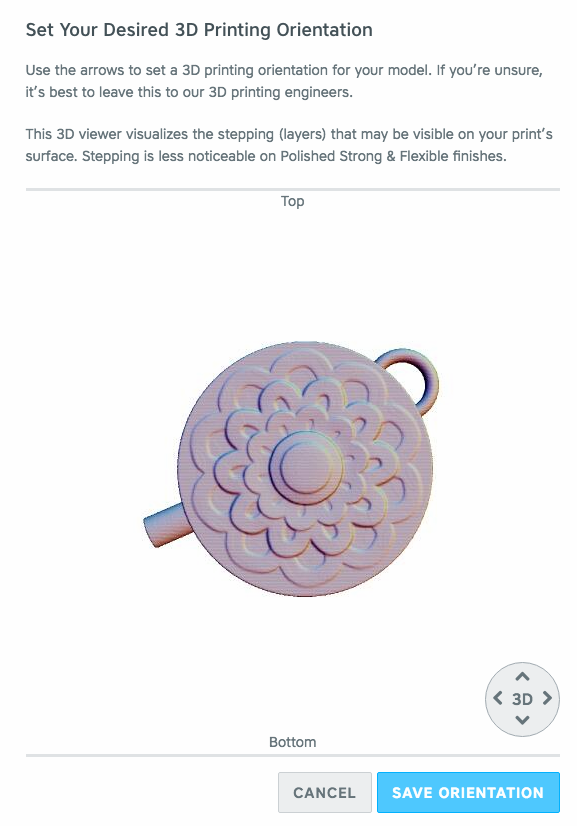

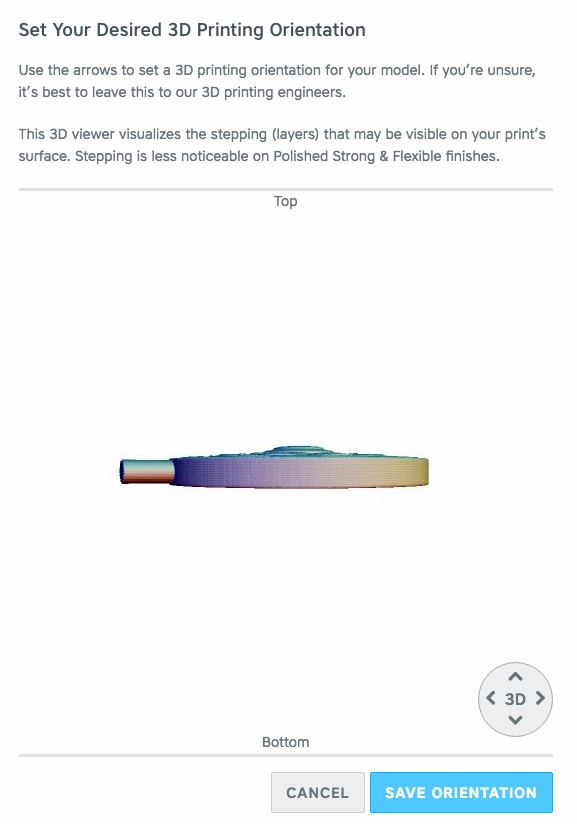

First of all, there are visible striations in the design. I had seen a setting that allows the designer to SET 3D PRINTING ORIENTATION. However, because of the placement on the page, I thought this related to the "Strong & Flexible Plastic" material only. It ends up it's just bad placement on their page...and I should have used this to adjust the layers of the print.

Interestingly, the size is almost dead-on. Shapeways shows that the CAD design was 1.8 cm, and my calipers reveal the print is only slightly smaller—1.798 cm. That's a VERY small difference. I allowed for a hole for a magnet, and it fits...but only barely. Simple fix, I'll just have to make that whole a little larger. By the time I cast the pendant, it would also shrink a little (wax shrinks as it cools), so I need to take that into consideration.

Another issue is the depth of the design. Because the design didn't stand out enough, the design could easily be polished off during finishing. I just need to increase that depth.

LOOKBACK: Shapeways allowed me to print this in wax with a design that was not raised enough. They have a page of design standards for each material on their site, and I would recommend highly that you check it out BEFORE starting your design. A good rule of thumb in sterling silver is to raise the design about 0.4mm from the surface, but that will vary depending on if you want the raw look or high-polished look. If you’re working in ZBrush, you can use the Transpose Line to measure the thickness if you’re using my techniques.

Overall, I'm excited, but a little disappointed. One thing I didn't realize is that Shapeways is using a technology called "Multijet Modeling" to print wax, and I don't think the resolution is as high as some of the SLA (stereolithography printers) I've looked into. The quality is not nearly as good as the samples I received from Solus and Formlabs.

So it's back to the drawing board and time to send another sample. Wish me luck!